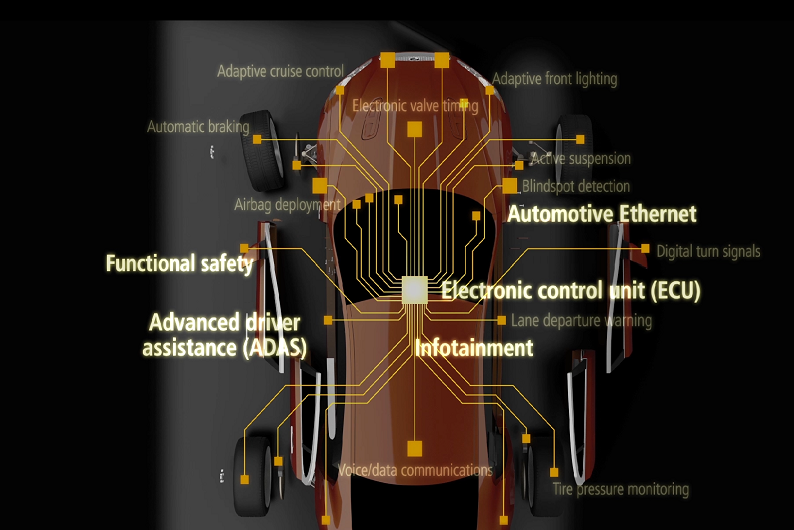

Today, more and more electronics from air bag sensors to safety and convenience features are being added to cars, revolutionizing automotive safety and electronics.

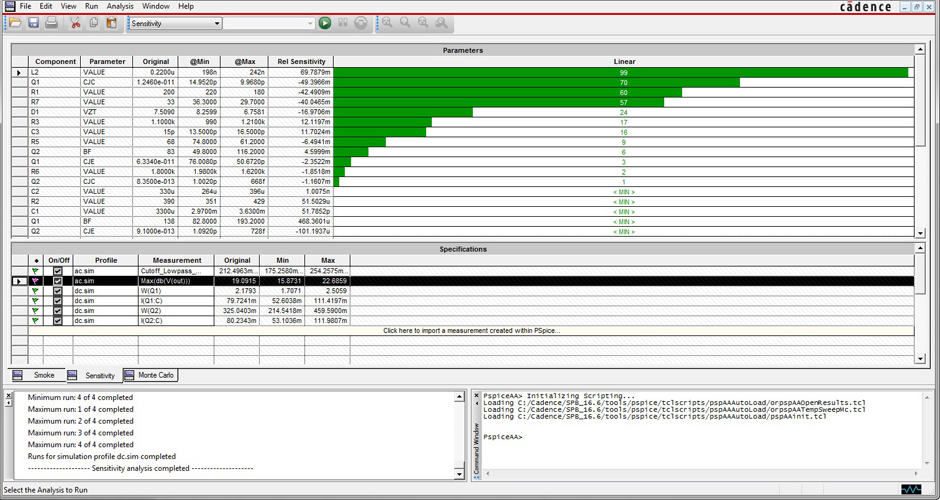

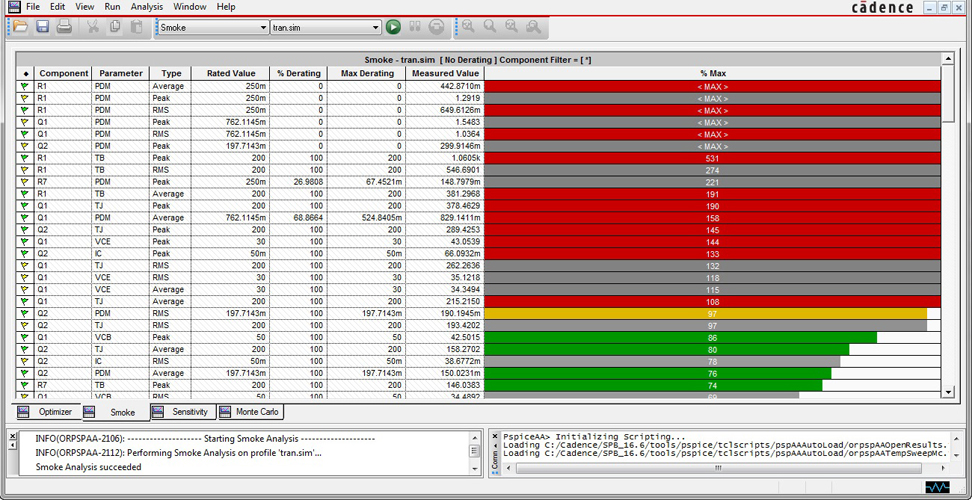

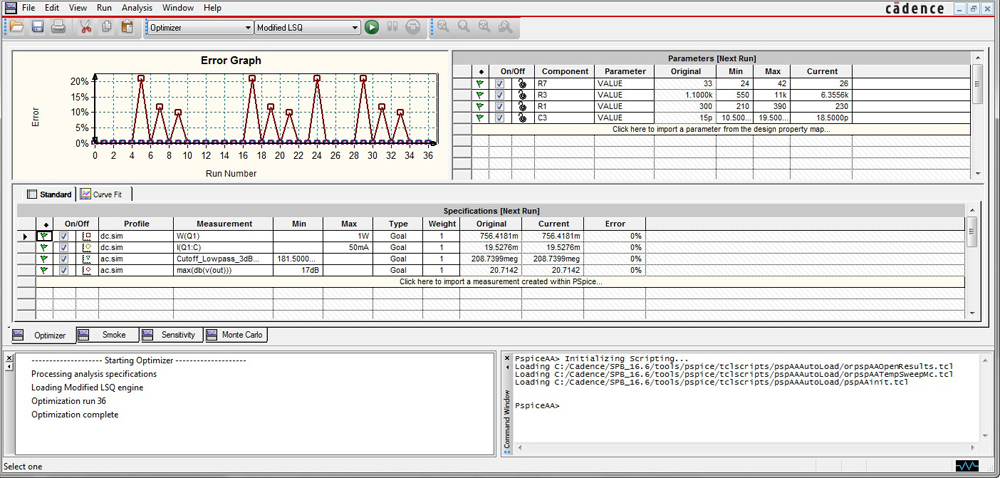

With new electronic technologies, there’s always a risk something will fail. Simulation of electronic circuits to verify their functionality and reliability based on component tolerances, temperature variations, and other parameters becomes critical. It is crucial for automotive companies to perform yield and reliability analysis through exhaustive simulations to ensure there are no recalls due to field failures.